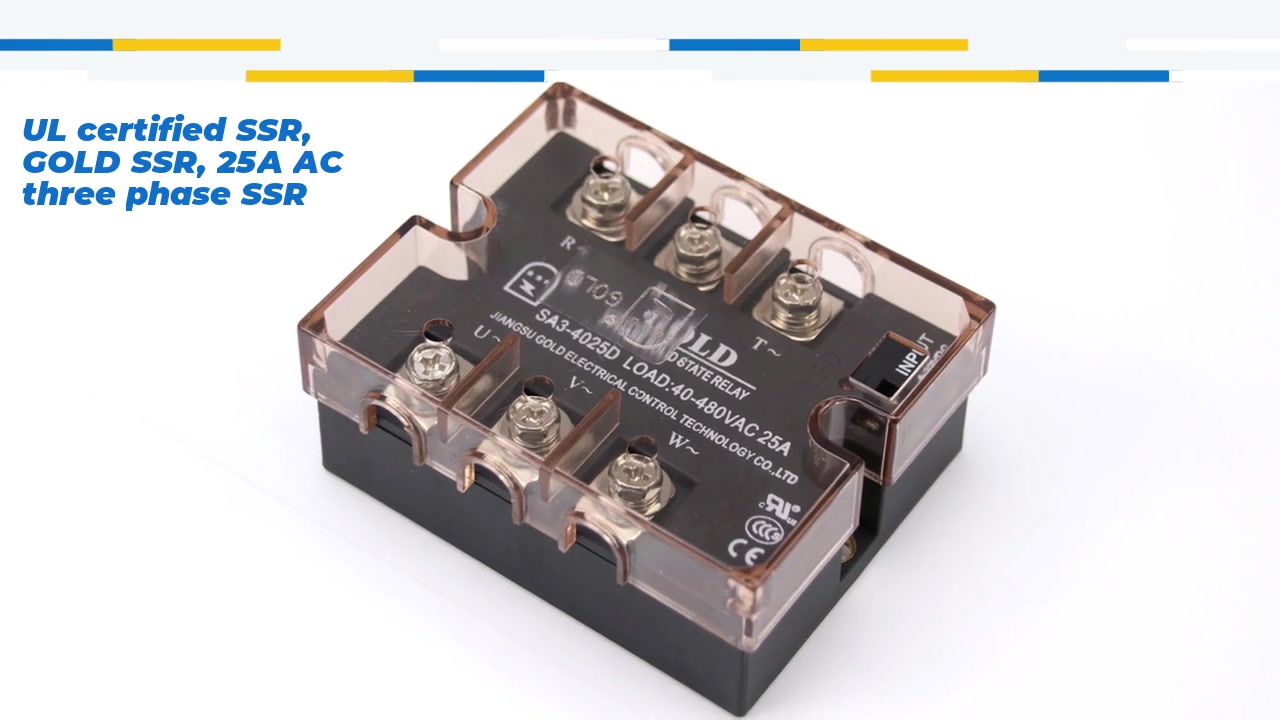

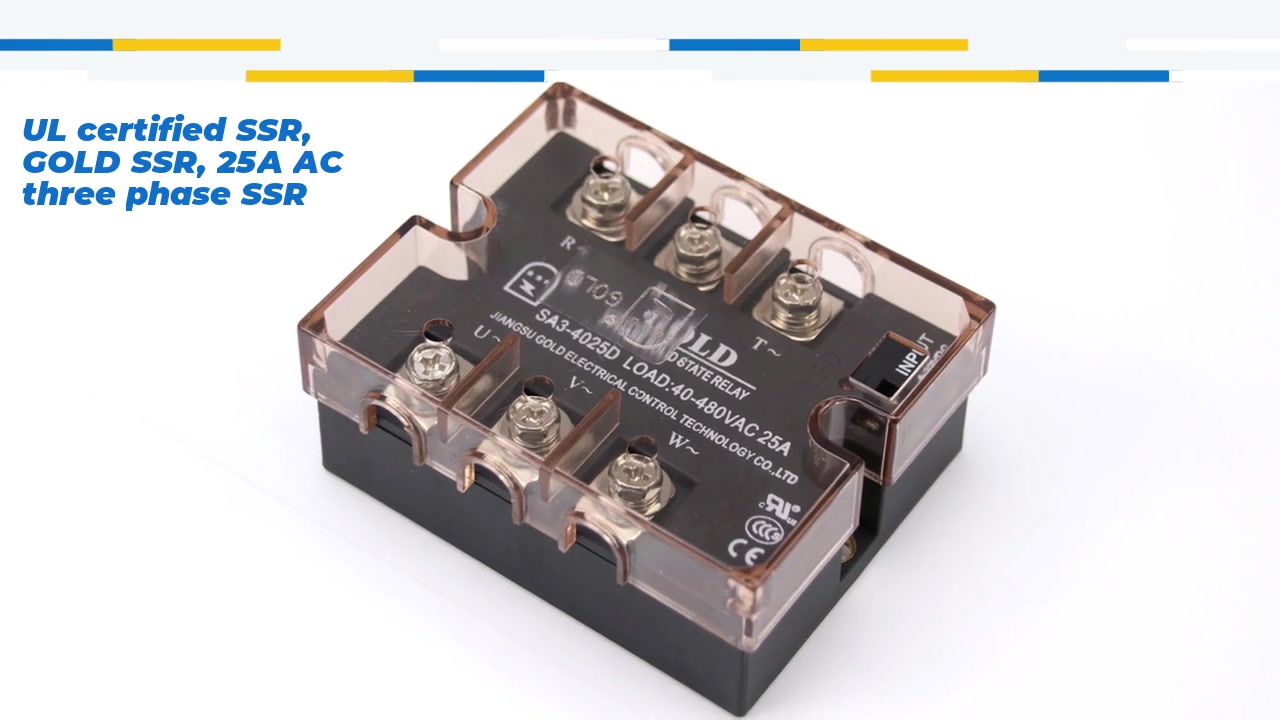

UL certified SSR, GOLD SSR, 25A AC three phase SSR, AC control AC solid state relay, input 90-280VAC, input with LED indication, output three phase, oupt current capacity 25A, output voltage 40-530VAC

+86-13795385467

+86-13795385467

ITEM | LOAD COLTAGE | LOAD CURRENT | INDICATION |

SA2-4060D/A | 40-530VAC | 60A | TWO LED |

SA2-4080D/A | 40-530VAC | 80A | TWO LED |

SA2-40100D/A | 40-530VAC | 100A | TWO LED |

SA2-40120D/A | 40-530VAC | 120A | TWO LED |

ITEM | LOAD COLTAGE | LOAD CURRENT | INDICATION |

SA3-4010D/A | 40-480VAC | 10A | INPUT LED |

SA3-4015D/A | 40-480VAC | 15A | INPUT LED |

SA3-4020D/A | 40-480VAC | 20A | INPUT LED |

SA3-4025D/A | 40-480VAC | 25A | INPUT LED |

SA3-4030D/A | 40-480VAC | 30A | INPUT LED |

SA3-4040D/A | 40-480VAC | 40A | INPUT LED |

SA3-4060D/A | 40-480VAC | 60A | INPUT LED |

SA3-4080D/A | 40-480VAC | 80A | INPUT LED |

SA3-40100D/A | 40-480VAC | 100A | INPUT LED |

SA3-40120D/A | 40-480VAC | 100A | INPUT LED |

Product parameters

input parameter | ||

Control voltage | 4-32VDC | 90-280VAC |

Turn-off | 1VDC | 15VAC |

Turn-on | 4VDC | 90VAC |

Control current | 6-25mA | 6-20mA |

output | ||

Load voltage | SA3-40/SA2-40 | SA3-66 |

40-480VAC | 40-660VAC | |

Min turn-on | 50mA | |

Max turn-on | 1.7VAC | |

Max turn-off | 10mA | |

Du/dt | 500V/us | |

Max turn-on time | random | 1/2circle+1mA |

Zero crossing | 10mA | |

AC control | 40mA | |

Max turn-off | DC control | 10mA |

AC control | 40mA | |

| 45-65HZ | |

Other data | ||

Min isolation | Input and output 2000VAC | |

Min insualtion | Input and output with the plate 2000VAC | |

Insulation resistence | 1000MΩ(500VDC) | |

Precautions for use

1. Product manufacturers have made great efforts on product quality and reliability, but the semiconductor power devices used in solid state relay, such as improper selection or use, will still lead to irrecoverable damage. In addition, due to grid voltage fluctuation (usually

A certain safety factor must be considered when selecting the type. For example: the long-term working current of electric heating should not exceed 60% of the current rated nominal value of SSR, and the working current of motor should not exceed 1 / 7 of the current rated nominal value of SSR.

2. When the long-term working current is greater than or equal to 5A, the matching radiator must be installed, and the temperature of radiator bottom plate shall not exceed 80 ℃

. If the ambient temperature is too high, air cooling must be adopted to accelerate the air flow in order to obtain better heat dissipation effect.

3. In order to ensure that the solid-state relay is in close contact with the radiator surface during the installation process to achieve better heat dissipation effect, Our company is equipped with special heat-conducting film or special heat-conducting silicone grease according to different current levels. During installation, please place the heat-conducting film between the bottom plate of solid-state relay and the contact surface of radiator in parallel and fasten the installation fixing screw. For those equipped with heat-conducting silicone grease, please evenly apply appropriate amount of heat-conducting silicone grease on the bottom plate of solid-state relay and fasten the installation fixing screw.

4. When the module is fastened to the radiator surface, M4 screw and spring washer are used to tighten the module with a torque of 4-6nm. After 3 hours of use, the module is tightened once with the same torque.

5. The recommended tightening torque of M3 screw at control end is 0.8-1nm, and that of M5 screw at load end is 1.9-2.1nm.

6. In order to prevent the breakdown damage of solid-state relay caused by load short circuit or overload of current and voltage in use, it is strongly recommended to install and use the matching special fast fuse (our company can provide supporting services). For inductive load, it is necessary to install varistor and RC absorption circuit at solid-state output end to prevent damage to thyristor in case of over-voltage. Selection of varistor (MOV): 430-470v for 240V, 680-750v for 40V and 1100-1200v for 660V.

7. The storage requirements of solid-state relay should be moisture-proof, moisture-proof, avoid rain, fall and violent fall. Store in a well ventilated area

In dry, non corrosive gas environment, the humidity of the environment must be less than 80%.

Copyright © 2022 Jiangsu GOLD Electric Control Technology Co., Ltd. - www.goldssr.com All Rights Reserved.